����ժ Ҫ����������Ͻ���ʵ����α��ڼ��ڳ����ӹ�ʱ, ��ог������λ�����Լ��о�֧���������λ��ԭ��, �����ͱ�֧�ܶ���ߴ糬������⡣�����ڴ�ͳ�������յĻ�����, ͨ���Ľ�װ�з�ʽ�Ͳ��ø���֧��, �����ʵ�ʷ��������ʵ�װ��λ�úͼг��������ӹ���֤, ���øüӹ������ɴ��������κͱ���о߰Ѽ�����, ��֤�ͱ�֧�ܶ���ӹ�����, ȡ�������õļӹ�Ч����

�����ؼ��ʣ����ͱ�֧��; ˫���ӹ�; ����֧��; ���α���;

����Abstract����In the process of turning the special-shaped thin-walled parts made of aluminum alloy, there are few clamping parts and the supporting parts of the clamping fixture are not in place, which leads to the problem of oversize of the end face of the oil pump support. On the basis of the traditional turning technology, the suitable clamping position and clamping force are analyzed by improving the clamping mode and adopting the auxiliary support. The machining results show that the machining scheme can greatly reduce the deformation of the parts, avoid the instability of the jig, guarantee the processing quality of the end face of the oil pump support, and obtain a good machining effect.

����Keyword����oil pump bracket; double top machining; auxiliary support; abnormal thin wall;

����0������

���������Զ��������ͱ�, ��Ϊ�Զ�����������Һѹ�ٿ�ϵͳ�Ķ���Դ�����ڸ�Ħ������װ��, ������ṹ�����ա���ƽ������������ŵ�㷺Ӧ���ڸ����Զ�������������, ����һ���Զ������� (AT) �ͱô���Ч�ʸ�, �ɿ��Ժ�, ��Ŀǰ�����г��������������ͱýṹ֮һ��

�����ͱ�֧���DZ������ͱõİ�װ������, �������ǽ��йص���������л�����, ���̶��������Զ���������, ����Һ��������Խ�, �̶�λ��, ����Һѹ�ͺ����͵����á��ͱ�֧�ܵ���Ҫ�ṹ�ص�:��״��������ƽ�桢����Ҫ��ߡ�װ���ױ��Ρ������Ѷȴ�����װ�з�ʽΪ������, �����ܽᴫͳ�ӹ�����������������ԭ��, �Ľ���������, �Ӷ��������ļӹ����ȡ�

����1����Ʒ�ṹ

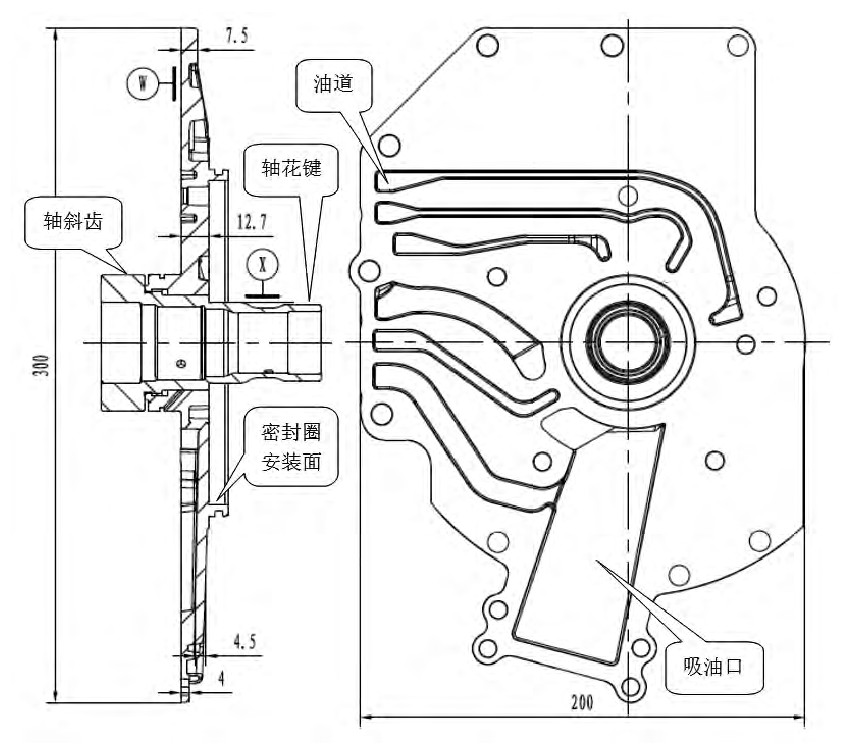

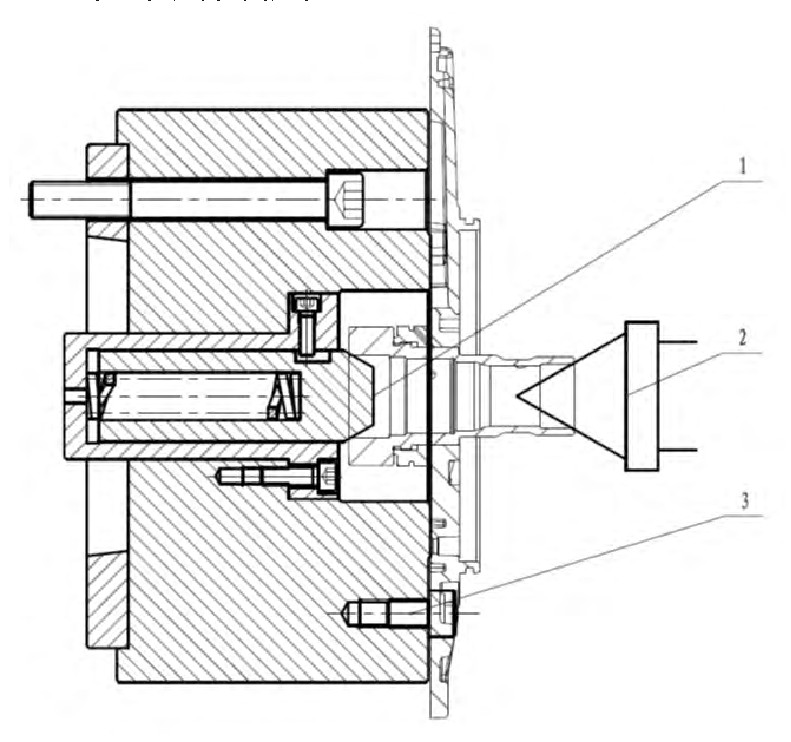

����ij6AT�ͱ�֧�ܽṹ��ͼ1��ʾ, ����״������, �ں�Ҳ������, �����ƺ�Ϊ���Ͻ�ADC12����W��Ϊ��λ����ܷ���, ��������Խ�, �����н����Ϳں������͵�, ���, W���ƽ���Ҫ��ϸߡ���XΪ�ᾱ, ����Բ����ת�ӳ����γ�Ħ����, ����ʱ, Һ����������������ת��Χ�ƻ�X��ת, �����ϻ�����Һ����������ᴫ��Ť��, ���, ����W����ڻ�X�Ĵ�ֱ��Ҫ��ϸߡ�����, �ܷ�Ȧ��װ�������ڰ�װ�ܷ�Ȧ��ʵ���ܷ�����, ��֤�������Ͳ�й¶, ���, �ô�������ҲҪ��ϸߡ�

����2�� ���շ���

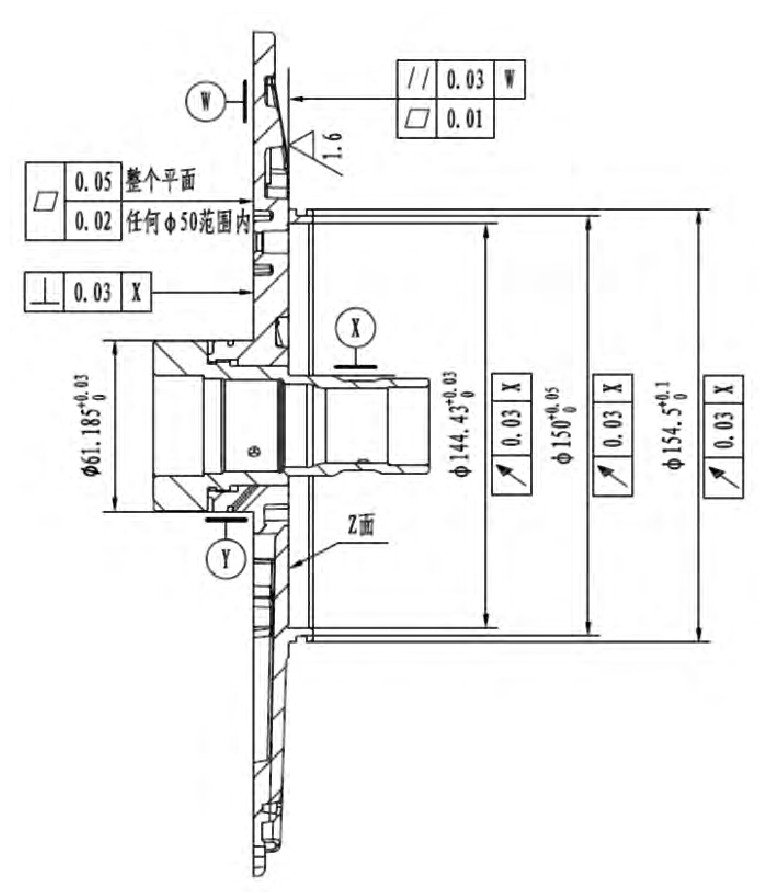

�������ͱ�֧�ܽṹ (ͼ1) ���ؼ��ߴ� (ͼ2) ������֪, ��֧��Ϊ���α��ڼ�, �����гߴ羫�ȡ�����ֲڶ�Ҫ����, ����λ����ҲҪ��ϸ�, �ر���ƽ���0.02mm����ֱ��0.03mm������0.03mmm��Ҫ��, ���ڶ�װ��Ҫ���, ��ʵ�ʼӹ����������ײ������λ�Ѽ����ȶ����Ա�֤��

����ͼ1 �ͱ�֧�ܽṹͼ

����2.1�� ��ͳ��������

������֧�ܴ�ͳ����������:����I→����II������Iʱ�гֻ�X, Z�������о߶���, �ӹ�������W�ͻ�Y, ͬʱȷ����X��Yͬ��, ���پ���IIʱ��X��Yת�����������;����IIʱ�гֻ�Y, ��W�������о߶���, �ӹ���3����ֱ���Լ�0.03mm���������������������ӹ�ʱ, ��������ƽ���0.02mm����ֱ��0.03mm������0.03mm�Ⱦ����ֲ�ͬ�̶ȳ���, ���д�ֱ�Ⱥ�������������, ������ڱ��λ�о߰Ѽ����ȵ������

����������ֱ�ȳ���ԭ��: (1) ����ԭ��֧�ܲ��������Ͻ�ADC12, ������֧�ܵIJ����ǻ���HT250, �������Ͻ�Ȼ�����, �ߴ��ȶ��Բ�, �������ϻ�����; (2) �о�֧��ԭ������Ͻ�ļӹ�����, ���ڸþ���Ҫ����ߵ����α��ڼ�, �ڼо����ʱû�п��ǵ�����֧��, ���������������; (3) �о�װ��ԭ����Iʱ��X�ij���ֻ��14.5mm, �гֲ�λ�������֧�ܽ϶�, �ڼӹ������моߴ��ڰѼ����ȵ����, ���»�W�������ϴ�, Ӱ���˴�ֱ�ȵ����ս����

����ͼ2 �ͱ�֧�ܾ���ͼ

����������������ԭ��: (1) ��ԭ������0.03mm�Ļ���X, ��װ�л���Y, ����һ���Ļ�ת�����; (2) �о�װ��ԭ��������б��ֱ���Ȼ�Yֱ��С, ���Ծ���II����Ҫ�гֲ�λ�ǻ�Y, ����Y�ij���ֻ��14.4mm, �뾫��I����, �ڼӹ������мо�Ҳ����ڰѼ����ȵ����, �����ת������������, ����ֱ�����������

����2.2�� ���ոĽ�

�����������Ϸ������о�, Ϊ����������κͼо߰Ѽ����ȵ��������, ��������һ���µ�װ�з�����ͬʱ, ������Ļ�X��ͨ��˫�����˵���ĥ�ӹ�������, �������X��װ�л�ת��Ӱ���С�����, ������I�;���IIͳһ����Ϊ˫�����ǵķ�ʽ��װ�����, �����˼гֲ�λ�϶�����İѼ�����, ��ʹ�ø���֧�Ŷ����ײ������εIJ�λ����֧��, ���������������, ������������Ρ������в������ַ����ӹ�������������:��ֱ��0.03mm�����Ϊ0.009mm, ����0.03mm�����Ϊ0.011mm, ����ߴ������Ҫ��, �Ҹ��ߴ�ļӹ�������ȴ�ͳ��������Ҫ�á��ɴ˿ɼ�, �˹��ոĽ�, ��ȡ�ýϺõ�Ч����

����2.3�� ����

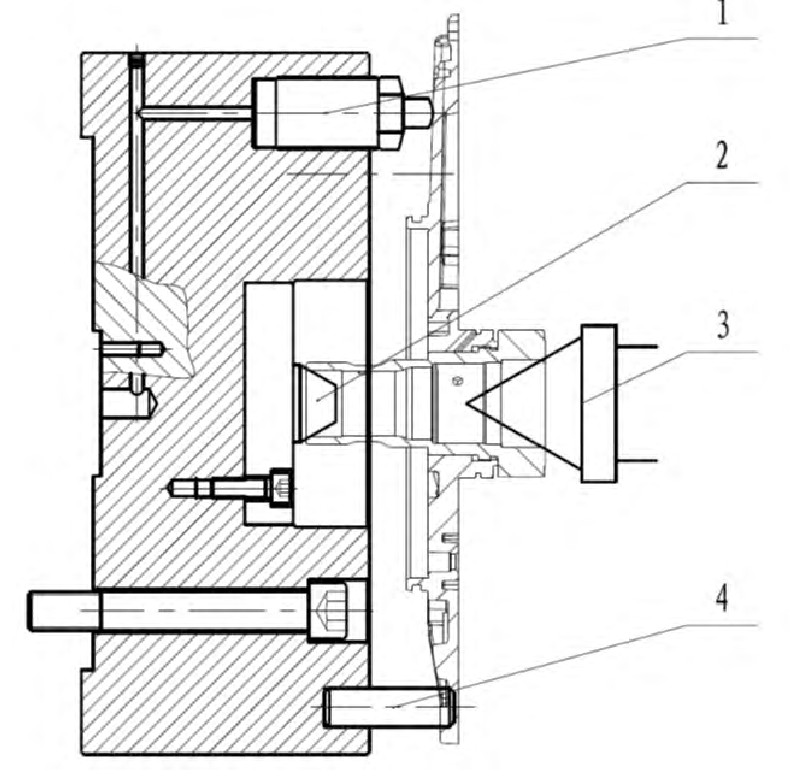

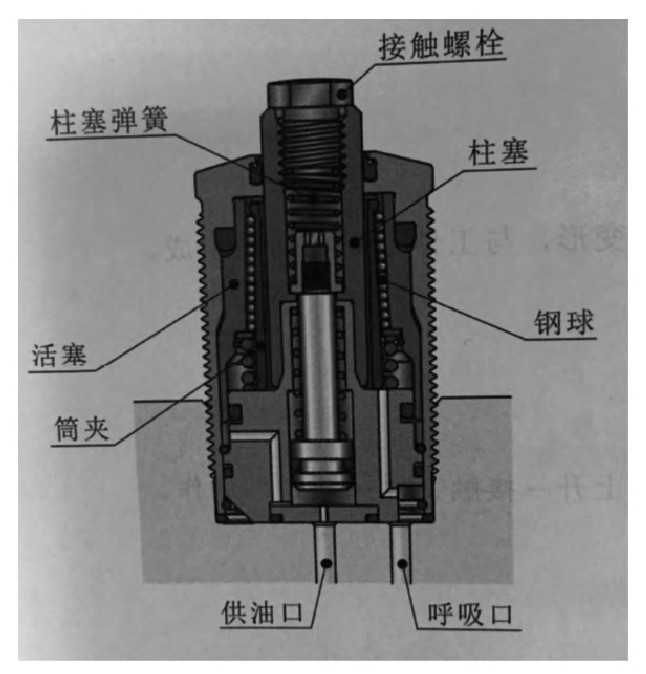

������ͼ3��ʾ, ����I�ļо���֧�Ÿ�1 (��5��) ���̶�����2����ת����3��������λ��4������������, ��֧�������˵ĵ��Ƿֱ���ڹ̶�����2�ͻ�ת����3��, ����֧�Ÿ�1�������α����������������в�ͬ��λ��֧��;ͬʱ, ����������λ��4��ֹ����ڼӹ�������������ת������, ֧�Ÿ�1���õ�����ѹ������֧�Ÿ�, �ṹ��ͼ4��ʾ, ����ѹ���ڹر�ʱ, ���������ջ�״̬;��������ѹʱ, ���������, �빤���Ӵ��� (������λ��) ֹͣ;Ȼ��, ��������ѹ�������¿�ʼ��ѹ, ������Ͳ�е�������ͨ���������������ǿ���ı�����, �Ӷ��γ�֧����, ��Ч������֧�ŵ����á�

����ͼ3 ����I�о�

����ͼ4 ֧�Ÿṹͼ

����ͬ��, ��ͼ5��ʾ, ����II�ļо��ɻ����1����ת����2��������λ��3������������, ��֧�������˵ĵ��Ƿֱ���ڶ���1�Ͷ���2��, ����������λ��3��ֹ����ڼӹ�������������ת��

����ͼ5 ����II�о�

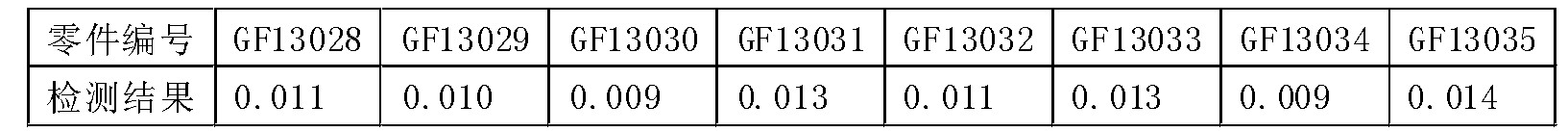

������1 ��ֱ�ȼ����

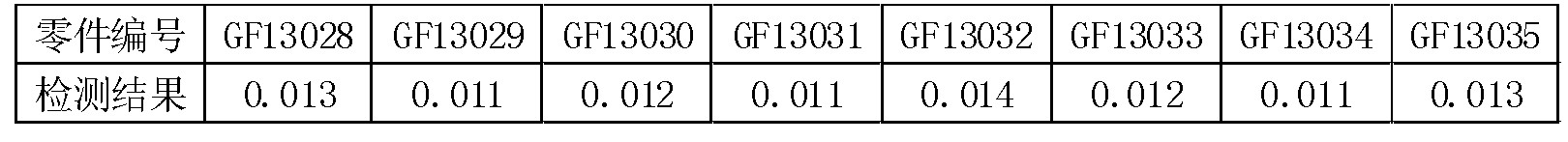

������2 φ144.43 (0, +0.03) ���������

�������Ϲ�װ���ŵ���: (1) �ı���װ�з�ʽ, ����˫���ӹ�, �����˼о߰Ѽ���������Ĵܶ�; (2) ͳһ��ǰ�������װ�л�, �����˻�ת�����������; (3) �����˸���֧��, �����α��ڵIJ�λ��������Ч��֧��, ������������ι�������ߴ糬�

�����Թ�װ�ļ���Ҫ����: (1) ����I��֧�Ÿ�1Ҫ����֧�Ų�λ�����֧�������к�����ѡ��, ��ͨ��֧�Ÿ�֧�������㹫ʽ (��ͬƷ�ƺͲ�ͬ�ͺŵ�֧�Ÿ�, ����㹫ʽҲ��һ��) �ó����֧����, ������ʵ������趨������ѹ; (2) ����I�Ļ�ת����3ѹ���趨�豣֤��������˶���������˶�; (3) ����II�Ļ����1�ͻ�ת����2��ѹ���趨�ڱ�֤��������˶���������˶���ͬʱ, ��Ӧ������ѹ���趨������������Ρ�

����2.4�� �����ӹ���֤

��������I��, ���������ͼ3��ʾװ��, ���֧�Ÿ�1֧���� (kN) ���㹫ʽ:0.7×P-0.91 (����P��ʾ����������ѹ (MPa) ) ����������ѹ, ͨ����μӹ���֤, �ܽ��������֧�Ÿ�1ѹ����Χ:20~25bar, ��ת����3ѹ����Χ:10~15bar��ͬ��, ���˷���, �ܽ������II���л����1ѹ����Χ:13~18bar, ��ת����2ѹ����Χ:10~15bar��

���������ϲ����ֱ�ӹ�8�����, ����I��Ĺؼ��ߴ紹ֱ��0.03mm���������1, ����II��Ĺؼ��ߴ�����0.03mm���������2��

��������ǰ�ڵ��Լӹ���֤��, ���������˴���������������, ���Լ�������з����ͼ���, ����ߴ�������ƷҪ��, �����йؼ��ߴ�Ĺ��������൱��, CPKֵ������1.33, ��������ߴ绹������1.67, ������������Ҫ��

����3�� ������

����ͨ���Ľ�װ�з�ʽ, ����˫���ӹ�, �����˼о���г������λ�ٵ�ԭ��, ����Ѽ�����, �����˸��ͱ�֧���ڼӹ������еĴܶ���ͬʱ, ��֤��ǰ������Ļ�ͳһ, �����˻�ת��������������, ������5������֧�Ÿ�, ��������������ε�����, ��֤�˲�Ʒ����, �ʺ������Ʋ�Ʒ������������

�����ο����ף�

����[1]������.��е�ӹ����������ž�ѡ[M].��е��ҵ������, 2004.

����[2]���.��е�ӹ������ֲ�[M].����������, 1991.

����[3]����.��е����������ֲ�[M].��е��ҵ������, 2006.

����[4]�����, ����, ��.�����о�����ֲ�[M].��е��ҵ������, 2004.